This approach will assist in preventing the overestimation or underestimation of demand. In business, the acronym ROP most commonly refers to the Reorder Point. This is a specific, predetermined level of inventory that triggers an action to replenish that particular stock.

- It helps businesses determine how much revenue they are generating for every dollar spent on advertising.

- Although the basic ROP formula is simple, various factors can greatly impact its calculation and effectiveness.

- The number you get for safety stock represents the amount of a certain item you can keep on hand in a given period to safeguard against stock-outs, based on previous sales.

- The daily sales velocity, or the average number of units you sell per day, differs for everything you sell.

- Now you’ve identified the upper limits of sales vs. the time it takes to receive new stock.

Understanding Business: The 4 Types of Inventory Management

- This ensures the customer is fully informed of the inherent risks and mechanics of options.

- You can even adjust how far back the system looks to calculate your sales velocity, allowing you to adjust for any potential seasonality or outlier sales.

- But in reality, some of your suppliers may not be able to deliver the materials on time because of their problems.

- It acts as a buffer, providing a cushion against variability and uncertainty.

- Almost everything we need can be found on the internet and is only a few clicks or taps away.

- Neglected inventory management leads to a decrease in customer loyalty, in addition to lost sales.

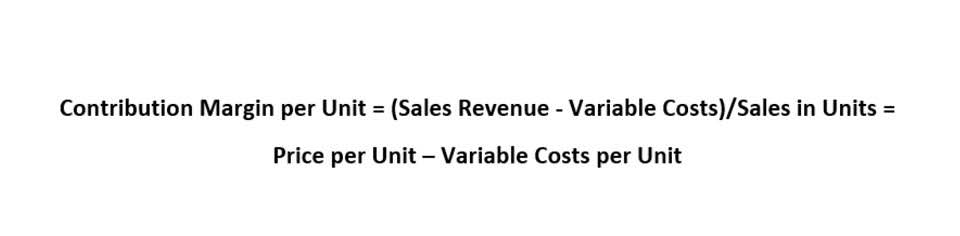

Implement dynamic safety stock calculations that adjust based on recent demand variability and service level goals. Integrate advanced demand forecasting methods with Reorder Point calculations, considering external factors like economic indicators or weather. Scenario planning can test Reorder bookkeeping and payroll services Points under different conditions to develop robust strategies. Finally, machine learning optimisation can continuously refine Reorder Points based on real-time data, learning from past performance to improve future outcomes. Average daily sales, or average daily usage, is simply the amount of product that you’re selling on a daily basis. It’s calculated by dividing your total sales by a specified number of days to see how much product you’ve sold during this amount of time.

Get in touch with an expert. Talk with sales.

Meredith Flora is a Content Marketing Manager at ShipBob specializing in supply chain management, logistics, and ecommerce fulfillment. She holds a BA in Communications and Public Relations from Virginia Tech, and brings 4+ years of expertise in supply chain content marketing. Meredith has authored 200+ blog posts, 20+ merchant case studies, and 10+ eBooks for ShipBob.

Calculating Reorder Points Are An Inventory Management Best Practice

The Reorder Point (ROP) is a critical concept in inventory Certified Public Accountant management that helps maintain a smooth product flow and optimise inventory costs. It represents the inventory level at which a new order must be placed to prevent stockouts before the next shipment arrives. For businesses of all sizes, accurately determining the ROP is essential to balance customer demand with holding costs. A well-calculated ROP safeguards against stockouts, preventing lost sales and customer dissatisfaction, while also avoiding overstocking, which ties up capital and increases storage costs.

Why is ROI important?

It’s the secret ingredient to ensuring you always have just the right amount of stock at the right time without overfilling your storeroom, or worse, running out. Leveraging sophisticated forecasting tools and analytics can improve the accuracy of ROP calculations. The main disadvantage of using ROP is that it can lead to inflexibility in pricing, as both parties have agreed to a static rate for their products or services.

Registered Options Principal (ROP): Meaning, Example

- The lead time it takes to replenish inventory is considered when calculating reorder points for different SKUs so that inventory levels do not reach zero.

- Sales volume is another important factor to consider as it pertains to setting safety stock for reorder point calculations.

- Register for an Easyship account today and you will gain access to the cheapest rates, instantly.

- For instance, a retail store might see a spike in sales during the holiday season, while a beachwear shop may experience its peak during summer months.

- Finally, performance monitoring with KPIs like inventory turnover rate and stockout frequency helps track the success of Reorder Point strategies.

For many businesses, a common approach is to calculate the average usage during the lead time and add a percentage of that as a buffer. For example, if a business uses 100 units during its average lead time, it might decide to hold an additional 20 units as safety stock. Reorder point refers to that stage of inventory management in which the inventory needs to be reordered to ensure the timely availability of goods for sales. It ensures that a business can have a minimum product quantity in storage to prevent operational disruptions from a stock out. At the same time, reorder points will prevent holding stock beyond the safety point to avoid incurring unnecessary storage costs. ROP signifies a critical rop meaning business juncture in your stock levels where hitting the reorder button ensures you’re perfectly balancing demand satisfaction and cost-effective inventory holding.